Our sandwich panel production technology

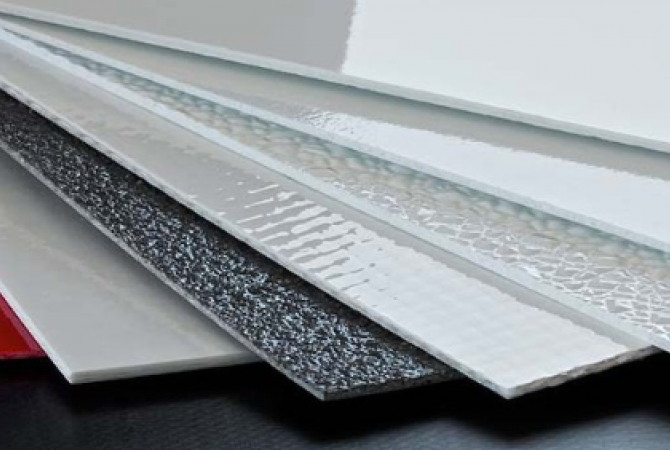

A simple sandwich panel consists of two fibreglass (GRP or FRP for short) or aluminium panels and a foam core.

The fibreglass panels are 0.8 to 3 mm thick, the aluminium panels 0.8 to 5 mm thick, and the visible side of both materials is covered with a protective film.

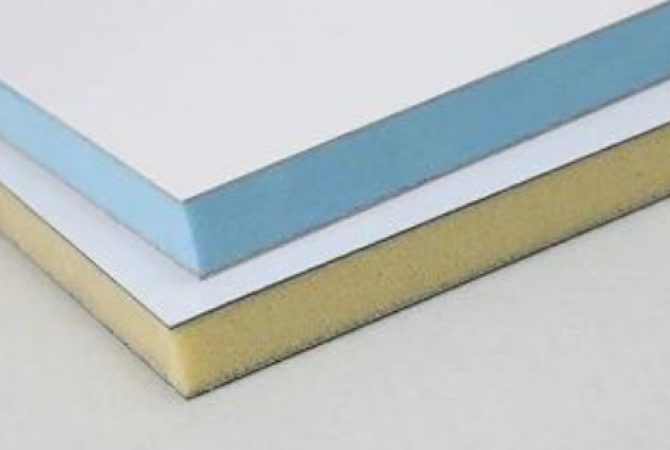

The core of the board shall consist of rigid polyurethane foam, abbreviated PUR or PIR foam, with a density of approximately 40 - 135 ± 3 [kg/m³] or extruded polystyrene, abbreviated XPS, with a density of 40 ± 3 [kg/m³]. The thermal insulation properties depend on the thickness of the foam. The density of the core influences the strength and weight of the sandwich panel.

The core is permanently bonded to the two outer materials by vacuum bonding in which air is extracted between the core and the shell.

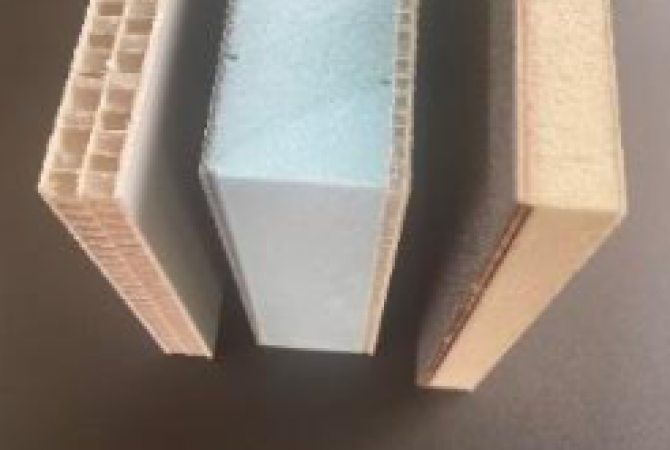

The core of the sandwich panel can be supplemented with reinforcement materials or profiled structural elements can be inserted for subsequent assembly, installation of process piping, handling, etc.

Construction of panels

1

Surface layer

Optional surface layeralmost any core-related material that is needed for your project.

Material: GRP / FRP, aluminium, stainless steel sheet, PVC.

2

Panel core

It provides thermal insulation properties. Its density kg/m³ determines the strength and weight of the sandwich panel.

Material: PUR or XPS foam

3

Reinforcement layer (optional)

Increases panel strength. Mainly used for used plastic sheets.

Material: Polypropylene (PP) film or waterproof plywood with a thickness of 4 - 9 mm.

4

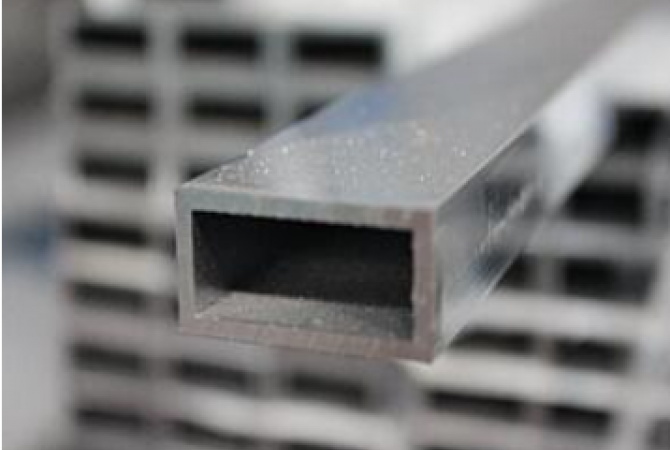

Inserts (optional)

We can go further and use reinforcing materials. This involves the insertion of structural materials to increase the strength of the sandwich panels. It is used as a structural and reinforcement element for subsequent assembly. Technology can be installed and distributed.

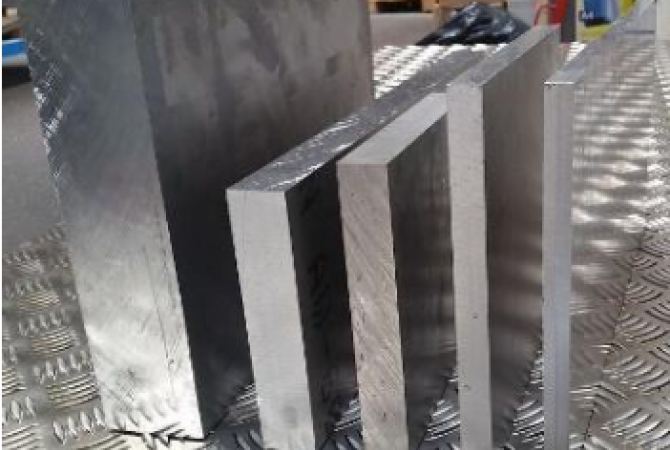

Material: The most commonly used aluminium profiles and plates are used.

5

Surface layer

Optional surface layer. Almost all core related material, which is the most suitable for your project?

Material: GRP/FRP, aluminium, stainless steel, PVC

Specifications of sandwich panels

Surface layer | GRP (German - Glasfaserverstärkter Kunststoff) / FRP (English - Fibre-Reinforced Polymer), aluminium sheet, PVC - suitable as a surface for mobile home floorboards, HPL (High Pressure Laminate), wooden plywood. |

Material core | PUR (polyurethane foam) in slab form, with a thermal conductivity coefficient, depending on the composition of the composite, of λ = 0,022-0,075 W/(mK) at a density of 40-135 ± 3 [kg/m³]. XPS (extruded polystyrene), with a thermal conductivity coefficient of λ = 0,03 to 0,04 W/mK at a density of 40 ± 3 [kg/m³]. |

Length | Max. 9000 mm |

Width | Max. 3000 mm |

Tloušťka Processing options | 10 - 200 mm or on request Forming, cutting, drilling, milling |